Thursday, 21 November 2024

DIY Lean-To Shed: Step-by-Step Guide for a Low-Cost Storage Shed

Building Your Own Budget-Friendly Lean-To Shed: A Step-by-Step Guide

Hey there, fellow DIY enthusiasts! So you're dreaming of a little extra storage space but don't want to break the bank? You're in the right place! Let's build a lean-to shed together. This guide will walk you through creating a simple, functional, and surprisingly affordable lean-to that'll be the envy of your neighbors (or at least, a really handy addition to your property). This isn't rocket science, folks, just some good old-fashioned elbow grease and a willingness to learn.Planning Your Lean-To Shed

Before we even think about grabbing a hammer, let's do some planning. This is crucial to avoid costly mistakes down the line.Choosing Your Location

Where will your lean-to live? Consider these factors:- Proximity to your house: This will make access easier. But keep in mind building codes regarding distances from property lines and structures.

- Level ground: Finding a relatively flat area will save you a lot of headache during construction. Slight slopes can be addressed, but level is best.

- Sun and shade: Think about whether you need a sunny spot or a shadier one for what you'll be storing.

- Access to utilities: If you're planning on adding electricity or running water later, this needs to be factored in now.

Size and Materials

How much stuff do you need to store? A small lean-to might suffice for gardening tools, while a larger one could house bicycles, outdoor furniture, etc. Remember, bigger means more materials and more work. For materials, let's aim for affordability:- Pressure-treated lumber: This is essential for the frame, offering resistance to rot and insects.

- Plywood or OSB (Oriented Strand Board): For the walls and roof. OSB is generally cheaper.

- Roofing material: Asphalt shingles are a cost-effective option. You might even find salvaged materials!

- Hardware: Nails, screws, hinges, etc. Buy quality hardware to avoid future issues.

Getting the Necessary Permits

This is a crucial, often overlooked step. Check your local building codes and obtain the necessary permits before you start building. It might seem tedious, but it'll save you potential fines or even demolition orders down the line. Better safe than sorry!Building Your Lean-To Shed: A Step-by-Step Guide

Let’s get our hands dirty! Remember to always prioritize safety. Wear appropriate safety gear, like gloves and safety glasses.Step 1: Foundation

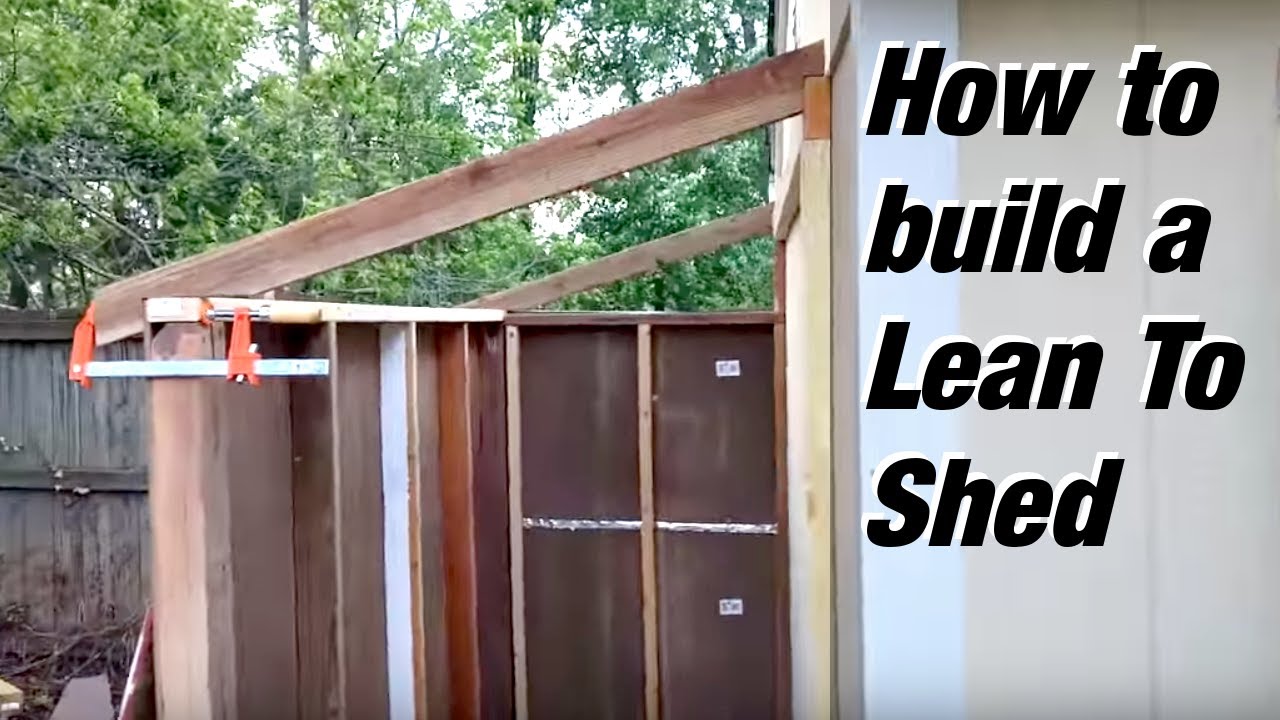

A simple concrete slab is ideal, but you can also use compacted gravel for a cheaper, quicker solution. If using gravel, ensure it's level and compacted firmly.Step 2: Framing the Walls

Using your pressure-treated lumber, build a frame for your lean-to's walls. This will be attached to the existing structure (house, fence, etc). Ensure the frame is plumb (perfectly vertical) and square (90-degree angles). This is where accurate measurements are vital!Step 3: Attaching the Walls to the Existing Structure

Carefully and securely attach your wall frames to the existing structure. Use appropriate fasteners, ensuring strong and stable connections. If attaching to a house, use appropriate flashing to prevent water damage.Step 4: Sheathing the Walls

Now it’s time to cover your frame with plywood or OSB. Make sure the sheathing is securely fastened to the frame.Step 5: Building the Roof Frame

The roof frame should extend from the wall to create the lean-to slope. Use pressure-treated lumber and ensure a sufficient slope to allow for proper water runoff.Step 6: Sheathing the Roof

Sheathe the roof in the same manner as the walls, ensuring all sheathing is securely fastened. Consider adding an extra layer of plywood for added strength and support.Step 7: Installing the Roofing Material

Follow the manufacturer’s instructions for installing your chosen roofing material. This is where a helper is invaluable.Step 8: Finishing Touches

Add doors and/or windows (if desired), trim, and any other finishing details to complete your lean-to. Consider adding weatherstripping around doors and windows to improve insulation and weather resistance.Tips and Tricks for a Successful Build

* **Measure twice, cut once:** This adage is especially important in construction! * **Use a level frequently:** Keeping everything plumb and level is key to a sturdy structure. * **Invest in quality tools:** This will make the job easier and more efficient. * **Don’t be afraid to ask for help:** A friend with construction experience can be invaluable. * **Take your time:** Rushing the process will likely lead to mistakes. * **Enjoy the process!:** Building something with your own hands is immensely rewarding.Frequently Asked Questions

Q: How much does it cost to build a lean-to shed?

A: The cost varies greatly depending on size, materials, and location. You can build a small lean-to for a few hundred dollars, but larger sheds with more features will cost significantly more.

Q: How long does it take to build a lean-to shed?

A: This also depends on the size and complexity, as well as your experience. A small, simple lean-to can be completed in a weekend for experienced builders, while a larger, more complex project might take several weekends or longer.

Q: Do I need any special skills to build a lean-to shed?

A: Basic carpentry skills are helpful, but this project is manageable for beginners. However, it's always best to have a general understanding of construction techniques. YouTube tutorials and online resources can be incredibly helpful!

Q: What are some common mistakes to avoid?

A: Skipping the planning stage, using inferior materials, not obtaining necessary permits, and rushing the process are all common pitfalls. Proper planning, quality materials, and patience are key to success.

Q: Can I build a lean-to shed against any type of structure?

A: The best structures to attach a lean-to to are those that are solid, level, and able to support the additional weight. Consult with a qualified structural engineer if unsure.

There you have it! A comprehensive guide to building your own lean-to shed. Remember to always prioritize safety, take your time, and enjoy the process. Happy building!

No comments:

Post a Comment

Note: only a member of this blog may post a comment.